In this interview, Growers Network talked with Warren Russell, CCO of Moleaer, about his company's nanobubble technology.

About Moleaer

Can you give our readers a little background on your company?

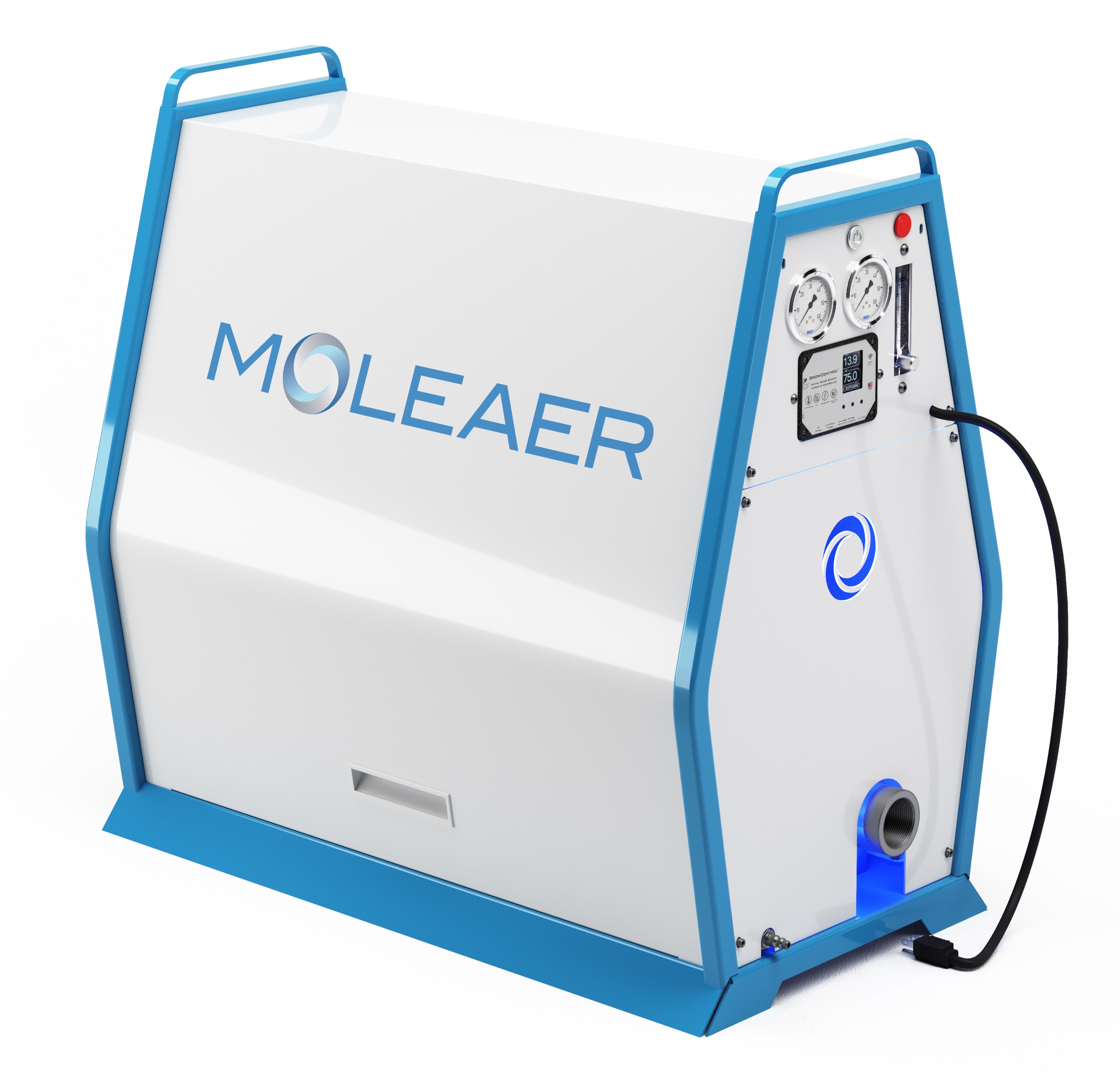

Moleaer (Latin for tiny air) develops industrial-scale gas injection systems that produce high concentrations of nanobubbles to alter the properties and functionality of water. Our systems are utilized in a variety of applications to enhance a wide range of processes, enabling a radical change in the economics of horticulture, separating metals, treating wastewaters and recovering oil.

What kind of new projects does Moleaer have going on? Anything you can talk about?

Moleaer is looking towards a very busy 2019. Since December, a number of new systems have been installed and we are starting to get cultivation data back from those projects and it is all very positive. We are transitioning very quickly from a handful of early adopters to being standardized into some of the largest facilities in the industry being built this year. It is incredibly exciting for the company and our technology to be receiving this high level of attention.

Moleaer in the cannabis space

What is something important that you’ve found most cannabis growers don’t consider with regard to their grow?

Generally speaking, aeration and dissolved oxygen in water is not very well understood. Unfortunately, there has not been a lot of in-depth research around the relationship of root zone oxygen and plant growth. Growers definitely understand the extremes – i.e. no oxygen is bad, but there is not a good understanding as to how plants respond to 7ppm of dissolved oxygen in the irrigation water compared to 20ppm. Some of this has to do with the limitations of conventional aeration equipment, while other issues are related to water management practices and irrigation methods.

What we continue to demonstrate to growers is that there is a direct correlation between the growing climate, light intensity and oxygen demand. Warmer temperatures and high DLI’s drive up the oxygen demand of the plant. If you don’t increase the level of oxygen in the substrate, then you will constrain nutrient absorption and limit growth.

Beyond photosynthesis, can you explain the overlooked importance of oxygen for plant growth.

Oxygen is vital to the central energy providing pathway of plant cells and it heavily influences plant metabolic rates and energy production. Elevating oxygen in the root zone, increases adenosine triphosphate (ATP) and enzyme production, facilitating better nutrient transport into the plant and to the shoots.

Oxygen also helps maintain the permeability of cell membranes, helping to keep them turgid and making plants more resilient to environmental stress.

Equally important to oxygen’s role in nutrient absorption, increasing oxygen levels in the root zone activates beneficial bacteria that helps to suppress pathogens like Pythium from proliferating. Additionally, oxygen enriched irrigation water prevents root asphyxiation due to lack of oxygen in the media or substrate.

Is there any evidence to show that oxygen nanobubbles improve plant growth?

Definitely, the easiest short-term thing you can measure is nutrient absorption. Plants grown in substrates receiving higher levels of oxygen in the irrigation water, absorb nutrients more efficiently. Monitoring EC levels going into the substrate and leaching out confirms the utilization rates. We see this translate into shorter internode spacing and consequently better bud density and yield per plant.

Please tell our readers about the technology/equipment necessary to make sure DO levels are sustained? Is it a complicated process?

Typically, our systems are installed on the irrigation day tanks, but they can also be installed on smaller nutrient mixing tanks. Fresh water is recirculated through our nanobubble generators where it is injected with oxygen nanobubbles and pumped back into the storage tank. Once the target dissolved oxygen level is reached, the nanobubble generator will turn off and the irrigation water will be fed to either the nutrient mixing tanks or inline fertigation system. When working in the super-saturation levels, the one provision everyone needs to take into account is that you do not want to air diffusers or other aspirators after super saturating the water. Doing so, will reduce the DO levels. We aim to deliver between 20 and 25ppm to the end of the emitters.

What has been the impact on Moleaer as cannabis becomes more and more accepted worldwide?

We see the rapid growth of legal cannabis cultivation as an important driver for new technology adoption in horticulture. It continues to help develop our own technology and product line for not only cannabis cultivation but all other horticulture crops.

Do you think more growers will realize the advantage of sustaining DO levels in their water?

Absolutely, the value of our technology seems to present itself pretty early to the grower. While super-saturating irrigation water with oxygen nanobubbles may have the potential to increase yields and cannabinoid content, we feel that one of the most appealing aspects of what our system does is give growers a little more room for error. Every grower makes mistakes along the way, oxygen enrichment helps reduce the impact of those errors. That insurance is proving to be valuable to growers.

Does Moleaer have any exciting plans for the future?

Application expertise is big part of our development and is one of the things that I believe sets us apart from other equipment manufacturers. We are constantly learning and adapting to what we learn in the field. That allows us to tailor our technology to meet the needs of growers. That being said, we love forging new paths. We are currently exploring different gas combinations to further enhance plant growth – this work will be something exiting to present in the future.

Growers Network would like to thank Warren Russell for taking the time to speak with us about Moleaer's technology.

Want direct access to cannabis professionals? Join our online community by clicking the join button below!

About the Interviewee

Warren Russell is an experienced business entrepreneur with over 15 years of business management experience within the wastewater treatment and environmental services industries of Southern Africa and the Middle East. Prior to leading the commercial efforts for Moleaer, Warren founded Erogfit USA and Evadine Technologies, which focused on environmental consulting and designing of wastewater treatment processes for municipal, industrial, oil and gas applications. Warren is a graduate of the University of South Africa.

10 Best Gift Ideas for Cannabis Connoisseurs and Growing Aficionados (2022)

December 7, 2022Developing and Optimizing a Cannabis Cultivation System

December 14, 2021Dealing with Insomnia: How Can CBD Help?

December 10, 2020Your Guide to Sleep and CBD

December 7, 2020

Do you want to receive the next Grower's Spotlight as soon as it's available? Sign up below!