Sara Schoenhals & David Berlin of Hydrologic Systems discuss the future of water regulations and how they will affect cannabis cultivation operations.

The following is an article produced by a contributing author. Growers Network does not endorse nor evaluate the claims of our contributors, nor do they influence our editorial process. We thank our contributors for their time and effort so we can continue our exclusive Growers Spotlight service.

As regulations on cannabis cultivation facilities continue to manifest, municipalities will further investigate power, water, and nutrient usage in the industry. Many operation managers and municipalities have not yet considered regulations regarding water usage and wastewater discharge in the cannabis industry. Regulations on these important parts of cultivation would impact cannabis producers dramatically, and possibly even putting some out of business due to slimmer profit margins and competition.

Let us not stick our fingers in our ears and pretend this day will not come. As the industry evolves, new water regulations could jeopardize an existing operation’s legal status. Drought-stricken states like California, Nevada, and Arizona will likely develop regulations on cannabis cultivation operations. Water volume usage and discharge will be something municipalities in those states will closely consider, if they haven’t already.

The two main water regulations on cannabis cultivation facilities concern volume usage limitations and wastewater quality regulations. If a facility is regulated based on the quality of its discharged water that runs into the sewer, the runoff water must be processed with a variety of methods. These methods include:

- Filtration and recycling

- Off-site shipping

- On-site evaporation

- Evaporation ponds

- Dilution, and/or

- Processing through artificial wetlands

If a municipality regulates a facility’s daily water volume usage, that facility must pursue one of the following:

- Cut back on planned or operational plant production

- Install a recirculating hydroponic system

- Filter and reclaim runoff water for irrigation, or

- Do all three

Water discharge regulations create a financial and legal incentive for cannabis producers to create facilities that feature “Zero Liquid Discharge.” However there are many challenges associated with building these types of systems as you will see.

Moving toward Zero Liquid Discharge means moving away from the traditional agricultural method of “drain-to-waste” systems. The runoff from a drain-to-waste system is almost always sent into the sewer systems, which is a big concern for regulators as such waste places heavy burdens on water treatment facilities and sewer systems. Closed-loop systems are possible, however, input costs can be higher when compared to a traditional drain-to-waste system. A system that can recycle all runoff water on a large scale is generally extremely specialized and the entire facility or operation must be engineered around this concept. Closed-loop systems require constant water testing and generally at some point require some sort of wastewater discharge, which then may also need to be processed further.

Editor’s Note: Curious about closed-loop aquaponic systems? We’re doing a series on them right now! Check out the first article here.

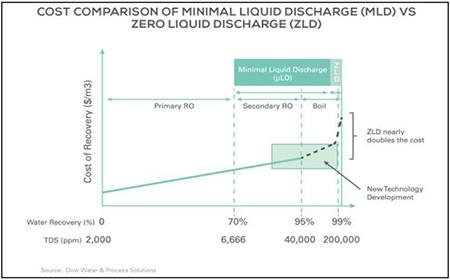

As an alternative, processing run-off water on-site for recycling and volume reduction is used by a large variety of industrial facilities today. Reverse osmosis (RO) filtration systems are the least energy-intensive and most economically sustainable way to remove dissolved solids from runoff water. However, the RO process produces highly concentrated wastewater that must be trucked off-site or evaporated.

Another potential option is a wastewater evaporator, which is extremely energy-intensive and produces a sludge-like waste that must still be trucked off-site.

Integrating RO and distillation/evaporation is generally the most economical way to truly achieve Zero Liquid Discharge; however, such systems are still extremely expensive. These systems are most efficient when they are designed to treat large volumes of water, which makes them the most suitable option for extremely large commercial/industrial operations. Smaller facilities will generally need to take the approach of water conservation via different growing methods that use as little water as possible, and reducing the volume to be shipped offsite for treatment.

While the above methods are all industrial solutions to treat agricultural runoff water, there are a few biological solutions that we haven’t mentioned yet. The main contaminants in runoff water can be analyzed in a laboratory and, in many cases, the runoff can be treated in artificial wetlands. In an artificial wetland, runoff water with dissolved nutrients is placed into the system and a variety of bacteria, plants, and other organisms convert the nitrogen-based fertilizers into actual biomass. This is a great solution for any facility that has proper permits and the requisite land to do this. The problem is that these types of systems do not work in an industrial area where there isn’t much land area available for relatively low prices.

What is the answer for facilities dealing with water volume usage limitations?

Many facilities dealing with daily limits on water volume usage filter their runoff water (including nutrient runoff and condensate water from climate control systems) to reuse for irrigation. These facilities typically use reverse osmosis to purify nutrient runoff water prior to irrigation. Condensate runoff (from climate control systems) does not need to be treated with reverse osmosis, and can be reclaimed using alternative treatment methods.

Editor’s Note: Condensate water can typically be treated with UV light to eliminate bacteria and mold, filtered, or also run through RO systems.

What about drain water discharge regulations?

Facilities dealing with concentrated water discharge regulations typically must truck all nutrient runoff water off-site. Many operations pay for this water to be taken away by the gallon.

However, one trick that minimizes the liquid discharge from a facility is using an RO system to further concentrate the contaminants from wastewater streams so that there is a smaller volume of wastewater that needs to be disposed of with reduced frequency.

Conclusion

While regulations will make life more difficult for cannabis cultivation facilities, we need to understand why these rules are being put into effect. Fresh water is a precious resource and must be conserved, particularly in dry areas. High levels of nutrients that are discharged into the environment can have dramatic negative consequences, which can be seen from industrial agricultural practices. Wastewater treatment plants may have difficulty treating a high volume of nutrient-rich water from hydroponic facilities, and regulations must take this into account to maintain proper infrastructure.

Whether your cannabis cultivation facility is already in operation or just being built, speaking with your municipality about current or impending water regulations will become critical to maintaining a sustainable, legal, and competitive operation. Not preparing for water regulations yet? They are likely to come — especially if you’re in an area where water is a scarce resource. Consider your options wisely.

10 Best Gift Ideas for Cannabis Connoisseurs and Growing Aficionados (2022)

December 7, 2022Developing and Optimizing a Cannabis Cultivation System

December 14, 2021Dealing with Insomnia: How Can CBD Help?

December 10, 2020Your Guide to Sleep and CBD

December 7, 2020

Do you want to receive the next Grower's Spotlight as soon as it's available? Sign up below!

Resources:

Want to get in touch with Hydrologic Systems? They can be reached via the following methods:

- Website: https://www.hydrologicsystems.com/

- Email: info@hydrologicsystems.com

Do you have any questions or comments?

About the Author

HydroLogic Purification Systems® specializes in a wide range of professional quality water purification products designed for use in many applications including gardening and hydroponics, residential, aquarium, or commercial.