Shane Banning of EZ-Clone goes over some common misconceptions and misunderstandings and comes up with ways to improve your aeroponic cloning technique.

The following is an article produced by a contributing author. Growers Network does not endorse nor evaluate the claims of our contributors, nor do they influence our editorial process. We thank our contributors for their time and effort so we can continue our exclusive Growers Spotlight service.

Tips and Tricks

While the internet can be a great thing, false information can spread very quickly on it. I’d like to take some time today to clear up some common misunderstandings and misconceptions about aeroponic cloning, and properly educate everyone reading this. At EZ-CLONE, we have been cloning plants 365 days a year for the last 18 years. Should you have any questions or concerns, please do not hesitate to ask us for assistance. You can find our contact information below.

In the world of plant propagation, many factors determine the success of your cloning cycle. From traditional methods of cloning in a medium, to the most advanced aeroponic methods, the outcome of a cycle is reliant upon one’s ability to control the environment and by creating the perfect conditions for that particular species and strain.

Plant Propagation Environment vs. Bacteria

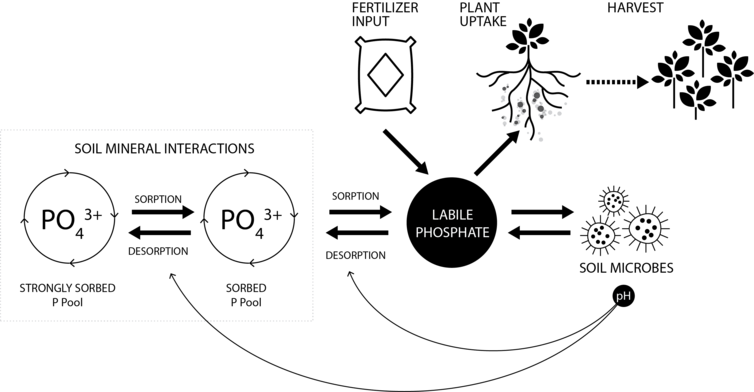

Plant propagation relies on the convergence of three critical factors; moisture, oxygen and heat. No matter what method of propagation, these three principles of cloning always apply. Cuttings yearn for a warm, moist, oxygen-rich environment. Unfortunately, so do bacteria and pathogens, the the leading causes of problems with plant cloning.

Bacteria and pathogens can be controlled by two methods:

- Creating a hostile environment to the bacteria via temperature control

- Using additives that combat the bacteria and pathogens on a molecular level.

In years past, it was a common belief that when cloning in an Aeroponic System, better results were achieved with lower reservoir temperatures because there was a significantly decreased risk of bacterial infection. In the past, even we at EZ-CLONE recommended cloning between 68 and 75 degrees Fahrenheit. By keeping the reservoir temperature lower, bacteria and pathogens are discouraged from growth, resulting in higher success rates.

However, this method is a double-edged sword. By making conditions inhospitable for bacteria, you’ve also made a more hostile environment for your cuttings, which can result in undesired consequences, such as prolonged rooting times.

The Frozen 2-Liter

While many folks believe the best way to lower water temps is by placing a frozen 2 liter bottle into their reservoir(s), this can also transfer harmful bacteria into their system(s). On top of that, this method requires frequent bottle swaping, and doing such causes a reoccurring fluctuation in water temperatures, something that cuttings DO NOT prefer.

Antibacterial Additives

The problem with the above methods is that instead of concentrating on creating and maintaining the perfect conditions for root development, a greater emphasis is placed on keeping bacteria at bay. This results in a less-than-optimal environment for root growth, meaning we need to reevaluate our priorities.

After extensive testing and research, we at EZ-CLONE have determined that warmer reservoir temperatures can accelerate rooting times. By developing an additive to directly combat bacteria and pathogens, which we named Clear Rez, we could open up a broader spectrum of acceptable cloning temperatures. With the use of Clear Rez, 100% success rates have become the norm at 85 degrees Fahrenheit, depending on species and strain. Remember, that there are always multiple solutions to any given problem, and finding the most practical solution is what learning and growth is all about.

If you do decide to use an antimicrobial additive in your reservoir, make sure to read the directions CAREFULLY, as there is a prescribed method of addition that should be followed very closely.

Air Pumps

EZ-CLONE has spent several years extensively researching the effectiveness and benefits of using an air pump in aeroponic systems. We have found no discernible benefits to using an air pump, in direct contradiction to several common myths. The air pump simply can become a vessel for introducing harmful bacteria and pathogens into a closed system.

Remember, we are specifically talking about aeroponic cloning, which means our cuttings/roots are suspended in midair. They are already absorbing all of the oxygen they require, which means an air pump is redundant. Furthermore, as the system cycles water via spray and reaccumulation, the water gets additional oxygenation. Air stones and air lines are just another thing to clean, potentially housing harmful bacteria. On your next cloning cycle, eliminate the air line and see for yourself. Results don’t lie!

10 Best Gift Ideas for Cannabis Connoisseurs and Growing Aficionados (2022)

December 7, 2022Developing and Optimizing a Cannabis Cultivation System

December 14, 2021Dealing with Insomnia: How Can CBD Help?

December 10, 2020Your Guide to Sleep and CBD

December 7, 2020

Do you want to receive the next Grower's Spotlight as soon as it's available? Sign up below!

Resources:

Want to get in touch with person? They can be reached via the following methods:

- Website: http://www.ezclone.com/

- Phone: 916-626-3000

- Email: info@ezclone.com

The dispensary and crew.

The dispensary and crew. Some of the clones.

Some of the clones.