In this contributor article, GrowFlux explains the importance of knowing the Coefficient of Utilization (CU) with regard to lighting for cultivation. You can read the original article here.

The following is an article produced by a contributing author. Growers Network does not endorse nor evaluate the claims of our contributors, nor do they influence our editorial process. We thank our contributors for their time and effort so we can continue our exclusive Growers Spotlight service.

When deciding how a particular LED light will perform in a grow operation, Photosynthetic Photon Flux Density (PPFD) is an important consideration. PPFD is affected by the design of fixture array, the height of the fixture above the canopy, the light intensity, and most importantly, the angular distribution of the light exiting the fixture - the factor that defines the “uniformity” of the fixture.

Coefficient of utilization (CU) measures what amount of light exiting a fixture will fall on a canopy area of a particular size, which is important to consider when designing an energy efficient Controlled Environment Agriculture (CEA) facility.

CU is the ratio of the total light emitted by the fixture against the light that falls on a canopy of a particular size. Light that does not fall on the canopy directly may be wasted (walls and floors) or may fall on adjacent canopy areas depending on the facility’s design (such as reflective walls).

How CU is Measured

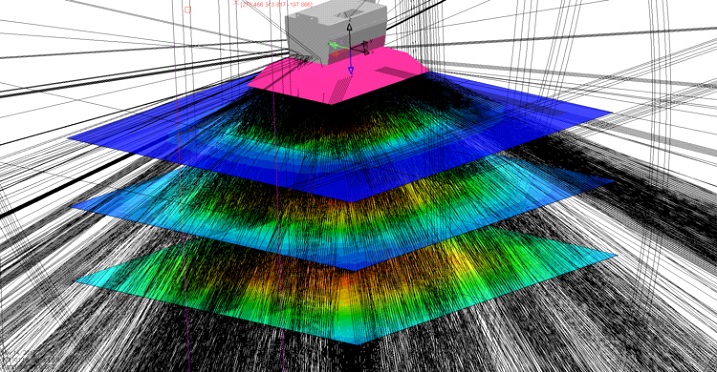

Since measurement techniques for determining CU are limited, the only accurate method to measure CU is simulation. In designing Growflux’s RAY Reflectors, we simulated the the entire fixture in a ray tracing tool using Monte Carlo calculation methods and ray data from the LED manufacturer to calculate the light output of a 3D model of FluxScale 6000TL. We accounted for all the materials in each product, each LED, operating and drive conditions, and fixture geometry.

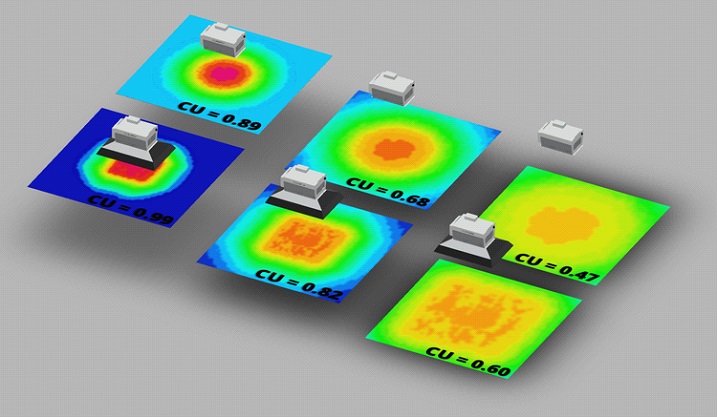

A Better Utilization of Light

Calculating CU from a simulation is a simple process; first calculate the entire light output of the fixture, then measure the output incident on various sized planes at different distances from the fixture. The ratio of these values is representative of the percentage of light that hits a geometrical plane of a certain size at a certain distance. As you will see, increasing the distance of the plane from the fixture results in a lower coefficient. Shown below are CU values for FluxScale 600TL on a 5x5 foot plane at three distances. Adding our FluxScale Reflector significantly increases the CU.

It is important to understand that the light that does not fall on the canopy directly under the fixture is not always wasted. With an efficient CEA facility design, this light can be reflected off highly reflective walls or will fall on canopy area adjacent to the fixture, depending on the design of the lighting array.

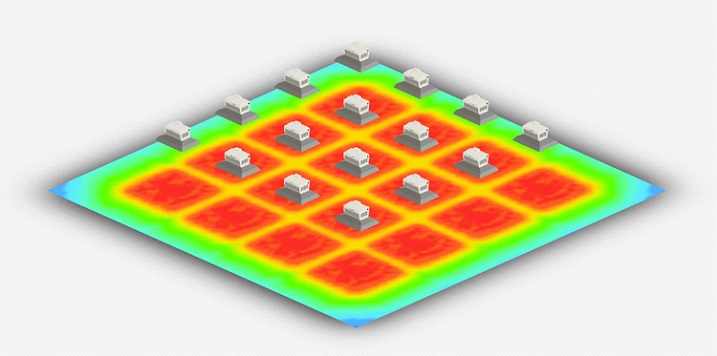

The RAY Reflector is designed to result in highly uniform lighting across large canopy areas, with whole array Coefficient of Utilization (CU) exceeding 0.95, depending on wall reflectivity and array layout

|

1ft distance |

2ft distance |

3ft distance |

|

|

FluxScale (no reflector) |

0.89 |

0.68 |

0.47 |

|

FluxScale with RAY Reflector |

0.99 |

0.82 |

0.60 |

Want to learn more about what GrowFlux has to offer? You can check out their website here. They have a ton of educational content on their blog if you want to read more about LED grow lights as well.

10 Best Gift Ideas for Cannabis Connoisseurs and Growing Aficionados (2022)

December 7, 2022Developing and Optimizing a Cannabis Cultivation System

December 14, 2021Dealing with Insomnia: How Can CBD Help?

December 10, 2020Your Guide to Sleep and CBD

December 7, 2020

Do you want to receive the next Grower's Spotlight as soon as it's available? Sign up below!

About the Author

GrowFlux offers tunable broad spectrum LED grow lights and connected agricultural sensors which help growers save energy, improve consistency, and enhance quality control. The GrowFlux Cloud is a quality control and management solution developed with the unique needs of Controlled Environment Agriculture (CEA) in mind, and is used in cannabis production, vertical farming, biopharmaceutical production, and cGMP managed CEA facilities.

Resources:

Want to get in touch with person? They can be reached via the following methods:

- Website: www.growflux.com

- Email: info@growflux.com