This educational text from Argus Controls’ highlights how lighting considerations in greenhouse design play an important role in the cultivation of any crop, including cannabis. The text has been split into several sections to make for easier reading, although you can see the original on Argus’ website.

Want to read part 2? Click here.

The following is an article produced by a contributing author. Growers Network does not endorse nor evaluate the claims of our contributors, nor do they influence our editorial process. We thank our contributors for their time and effort so we can continue our exclusive Growers Spotlight service.

Disclaimer

This article was originally written and published by Argus Control Systems Ltd. The original article can be found here.

Part 3 - Artificial Lighting

In commercial production, artificial light sources are used in a variety of ways:

- Replacement lighting - complete replacement of solar radiation for indoor growth rooms and growth chambers.

- Supplemental or production lighting – used in greenhouses to supplement periods of low natural light.

- Photoperiod lighting – used to stimulate or influence photoperiod dependant plant responses such as flowering or vegetative growth.

The need for and quality of artificial illumination required is determined by a number of factors including:

- Light requirements of the species being grown.

- Natural daylength.

- Average hours of sunlight.

- Sun angle and intensity (latitude and weather).

- Amount of structure-induced shading.

Replacement Lighting

Because sunlight is a free input, it is usually best to take maximum advantage of the ambient solar conditions. Seldom has it been shown that 100% artificial lighting is economically viable for legally grown commercial crops. Even though it is highly variable, sunlight is far more intense than any commercially practical artificial sources and it is has a broader, fuller spectrum of photosynthetically active wavelengths.

Editor’s Note: This article was written when cannabis was not commonly grown on large, legal scales.

When constructing growing environments where the majority of lighting is from artificial sources, it is normal to mix lamp types to achieve a more balanced spectrum, and many configurations have been devised and studied. However, there remain practical difficulties in achieving a uniform distribution of light when using mixtures of lamp types.

Supplemental Lighting

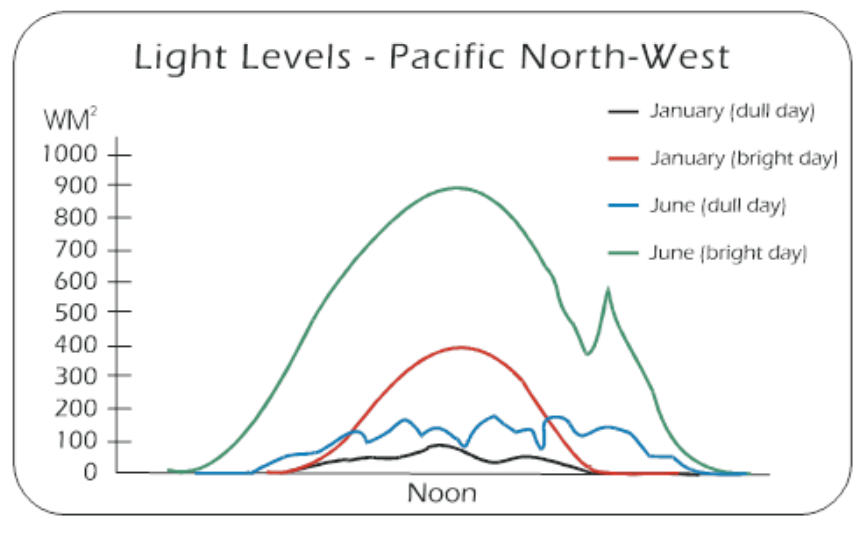

For commercial greenhouse production, supplemental lighting is most beneficial in areas that receive less than 4.5 hours average daily sunshine. In many greenhouse growing regions this occurs in winter as a result of the combination of high northern or southern latitudes and overcast weather. For example, parts of Washington, Oregon, and southwestern British Columbia, average just 2 – 2.5 hours of sunshine per day during the winter months, and because of the relatively low sun angle, the overall intensity can be as low as 5% of summer levels.

Types of Lamps

In lighting terminology, the word ‘lamp’ refers to the light bulb or tube, and the word luminaire refers to the entire light fixture: lamp + reflector + ballast + housing. When discussing and comparing light sources it is common to just refer to the lamp types. However, most specialized lamps require custom housings, ballasts, and reflectors.

Consequently, for a given lamp type, there may be several configurations of luminaires available. Some are designed specifically for horticultural use, and others for different applications. It’s important to remember that the luminaire type, and the reflector design in particular, play a very important role in the horticultural effectiveness of the lamp.

A perfect artificial light source would provide 100% conversion of electrical energy into light, in a spectrum optimally balanced for plant growth. In reality, no such light source exists, not even the sun. Therefore, when evaluating artificial light sources, several factors and compromises must be taken into account. Lamp efficiency, lifespan, intensity, spectral quality, cost, and electrical requirements must be weighed against the crop demands and the intended application before selecting any supplemental or solar replacement source.

Conventional horticultural light sources can be grouped into three categories:

- Incandescent

- Fluorescent

- Discharge

Editor’s Note: At the time this article was written, LED horticulture lights were largely experimental and not useful at a commercial scale. Since that time, however, some LED horticulture lights have shown significant promise.

Incandescent Lamps

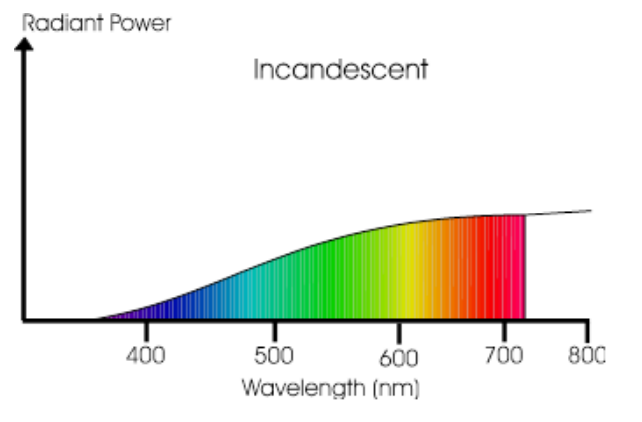

Incandescent lamps typically emit light as a result of the heating of a tungsten filament to about 2500 Celsius. At this temperature, the emission spectrum from the filament includes a substantial amount of visible radiation. Only about 15% of the energy (watts) applied to an incandescent lamp is radiated in the PAR (photosynthetically active radiation) range of 400-700 nm. 75% is emitted as infrared (850-2700) nm, and the remaining 10% is emitted as thermal energy (> 2700 nm).

Since they are not very light efficient and they have a relatively short lamp life, incandescent lamps are usually not the most effective radiation sources for providing supplementary light for photosynthesis. They are, however, useful for phytochrome-dependent photoperiod control since they are relatively inexpensive to install and operate, they can be cycled on and off frequently, and they produce large amounts of red and infrared radiation.

This is why incandescent sources are often the lamp of choice for night break, and long-day lighting applications, particularly when other supplementary lighting sources are not installed. Typically, incandescent lights are used to break the night into two or more short-dark periods, thereby stimulating a long-day growth and development response in the crop. This may be used to promote flowering in long day species such as asters, azaleas, and fuchsias, or to delay flowering in short day species such as chrysanthemums, begonias, and poinsettias.

Since plant photoperiod response occurs under relatively low light intensities, less power is needed for photoperiod lighting than for supplemental lighting. The long standing recommendation for maintaining vegetative growth in chrysanthemum crops has been to place strings of 60 watt bulbs spaced 1.2 meters apart and suspend them 1.5 meters above the crop. This will provide sufficient photoperiod lighting for a 1.2 meter bed or bench.

Similarly, any combination of incandescent lamp wattage, spacing, and mounting height that can produce an output of at least 10 foot-candles evenly on the crop will work. This corresponds to about 16 electrical input watts per square meter (rated bulb wattage divided by the area illuminated). Special reflector bulbs are available to focus most of the radiation downwards or do-it-yourself reflectors are often fashioned from aluminum foil pie plates.

Fluorescent Lamps

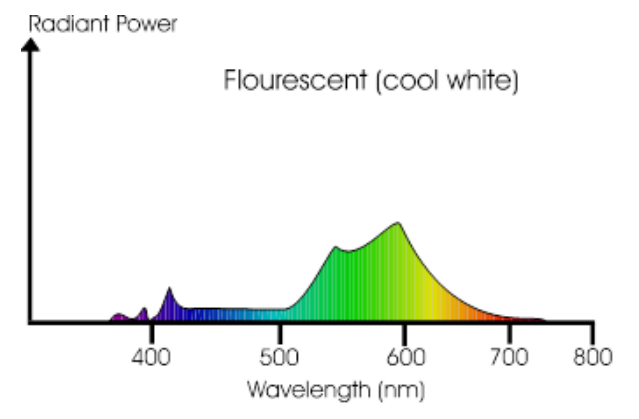

Unlike incandescent lamps, which emit light from the heating of a metal filament, fluorescent lamps produce light from the excitation of low pressure mercury vapor in a mixture of inert gases. A high voltage differential at the electrodes on opposite ends of the lamp tube produces an arc through the gas mixture exciting the mercury ions, which in turn emit short wavelength (primarily UV) radiation as they drop back to a ground state. Special fluorescent coatings on the glass tube walls are activated by this short wavelength radiation producing a discharge of visible spectrum radiation from the lamp. By altering the composition of the fluorescent coatings, variations in spectral output are accomplished.

Fluorescent lamps are more light efficient than incandescent lamps and they have a much longer life span. They also run cooler and produce a fairly balanced spectrum in the PAR range. They operate best in warm temperatures with peak light output occurring when the lamp wall reaches about 38C. As the temperature decreases, light output falls dramatically to only 50% when the lamp wall temperature is 16C. Light output also declines as fluorescent lamps age, falling to about 60% after 10,000 hours.

Fluorescent lamps are available in three load types:

- Normal output 400 mA.

- High output 800 mA.

- Very High output 1500 mA.

One disadvantage of fluorescent lamps is their relative bulk in relation to output. Even the very high output fixtures and the new slimmer T8 tubes, when configured in sufficient densities for supplemental lighting, can cast considerable shadows that can interfere with ambient lighting. They are however, useful in growth chambers and particularly in multiple tier applications since their relatively cool operating temperatures allow them to be mounted in close proximity to plant surfaces.

Fluorescent lamps are available in a range of spectral qualities. Relatively inexpensive cool white lamps are fine for supplementary lighting, and ‘full spectrum’ lamps are available for replacement lighting applications.

High Intensity Discharge Lamps (HID)

Modern high intensity discharge lamps are similar to fluorescent lamps in that they introduce an electrical arc into an elemental gas mixture. This produces a spectral discharge that is characteristic of the elements in the arc. However, they differ from fluorescent lamps in that no fluorescing powders are used on the lamp glass, and the elemental gases are heated under much higher vapor pressures and temperatures.

The light intensities and efficiencies obtained by high intensity discharge are higher than either incandescent of fluorescent lamps. The two most common discharge lamps used in modern horticulture are metal halide and high pressure sodium lamps.

Metal Halide (MH)

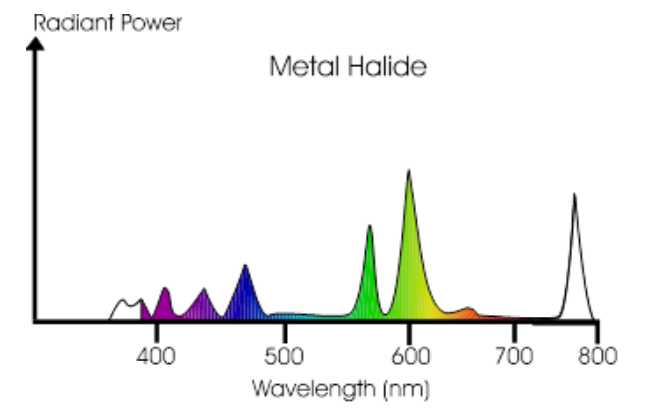

Metal halide lamps use mercury vapor in a quartz arc tube and various iodide mixtures of sodium, thorium, or thallium.

The electrical arc vaporizes the halides, heating them to a plasma state, whereupon they emit line spectra characteristic of the elements in the plasma. Metal halide lamps produce a relatively full spectrum of white light that is often preferable to the yellowish light of high pressure sodium when used in public or retail horticultural environments.

They provide the best overall spectral distribution of all horticultural lamps, but are not quite as efficient in energy conversion as high-pressure sodium lamps in the PAR range, particularly in the yellow-red spectra.

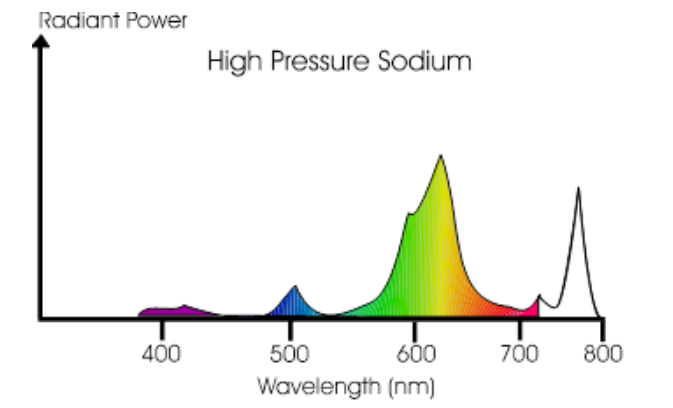

High Pressure Sodium (HPS)

High pressure sodium has become the most popular lamp type for commercial supplemental lighting in horticulture. High pressure sodium lamps produce light from an arc-induced discharge in a mixture of sodium vapor and mercury vapor. The emission spectra is highly concentrated in the yellow-orange-red range (500-650 nm) but is fairly low in the blue range.

Used as a replacement light source, HPS lamps may require supplementation with fluorescent, mercury vapor, metal halide, or other light sources high in blue light. However, they are fine as a supplemental source since adequate amounts of blue light are usually available from ambient light to sustain blue-light-specific plant morphogenic responses.

HPS lamps have a long life, and are available in a range of wattage sizes as well as ballast/ reflector configurations optimized for horticultural production.

Low pressure sodium lamps which, although more efficient in their conversion of watts to lumens than HPS, produce a spectral distribution so narrow that they are of little horticultural use.

Radiant Efficiency for Supplementary Irradiation

The following table summarizes the relative radiant efficiencies for the standard illumination sources used in horticulture.

| Radiation Soucre | Efficiency Lumens Per Watt | Average Life (in Hours) |

| Incandescent | 12 - 26 | 1,000 - 3,000 |

| Metal Halide | 80 - 90 | 8,000 - 20,000 |

| High Pressure Sodium | 117 | 15,000 - 24,000 |

| Fluorescent | 52 - 84 | 12,000 |

| Mercury Vapor | 50 - 60 | 24,000+ |

Luminaire Placement and Light Distribution Uniformity

The degree of growth uniformity in a crop is influenced directly by the uniformity of light falling onto the crop canopy. The manufacturers of horticulture luminaires often recommend specific grid and spacing patterns for various intensities and lighting configurations.

These are determined by the specific lamp output, crop requirements, and luminaire reflector designs. Often, an overlapping pattern is designed with some additional modifications to lamp placement and density at the crop margins to produce the most uniform lighting over the entire cropping surface.

Supplementary Illumination Levels and Duration

It has long been accepted that it is more efficient to provide a lower amount of irradiation over a longer period than a high amount over a short period. For example, it is usually better to light a crop at 5 W·m-2 for 18 hours, than at 10 W·m-2 for 9 hours, provided there are no photoperiod requirement conflicts. Not only do the plants use the light more efficiently, but the total number of luminaires and electrical service loading can be reduced, thereby reducing capital investment costs.

It has also been shown that the maximum incremental benefit of supplementary illumination occurs when the plants are lit beyond the daylight period, so lighting at night is generally more effective than lighting during the day period.

During periods of low ambient light levels, it is a common strategy to light during the day wherever levels fall below a predetermined set point, and to extend the lighting duration period to the maximum recommended for the crop. For example, cucumbers and roses can be illuminated for 24 hours per day, while tomatoes and most bedding plants should only be lit for 16 - 18 hours to avoid problems with flower delay.

In greenhouses, supplementary light levels have been suggested ranging from 3 W·m-2 for ferns and other low light crops, to 20 W·m-2 for vegetable crops and propagation areas.

10 Best Gift Ideas for Cannabis Connoisseurs and Growing Aficionados (2022)

December 7, 2022Developing and Optimizing a Cannabis Cultivation System

December 14, 2021Dealing with Insomnia: How Can CBD Help?

December 10, 2020Your Guide to Sleep and CBD

December 7, 2020

Do you want to receive the next Grower's Spotlight as soon as it's available? Sign up below!

Resources:

Want to get in touch with Argus? They can be reached via the following methods:

- Website: http://arguscontrols.com/

- Email: sales@arguscontrols.com